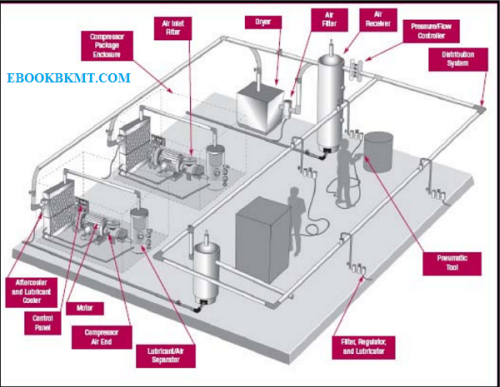

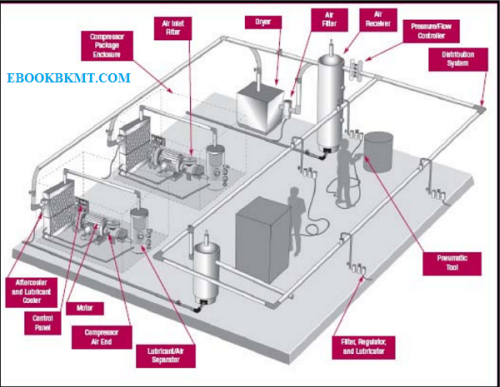

A pneumatic system consists of the supply unit – which includes compressors and air handling parts such as an inlet air filter, a water post-compression cooler, an air dryer, a moisture trap, and a dissipation unit. consumption – includes storage, distribution and end-use equipment such as accumulators, piping systems, filters, regulation and lubricating equipment.

– Inlet air filter: Prevent dust from entering the compressor: Inlet dust causes valve blockage, wear of screw and other parts, etc.

– Accumulator: Air storage tanks are used to store gas and reduce compressed air pulses – reducing pressure changes from the compressor.

Components of a compressed air system

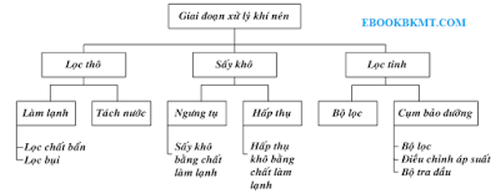

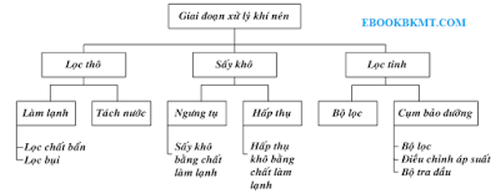

Compressed air systems must always have components to handle compressed air (coolers, dryers, condensate traps) and usually have to go through three main stages: Pre-filtration, drying and fine-filtration to minimize the amount of matter. Contaminated dirt is transported in the air ducts causing wear and rust in the pipes and in the control system elements.

+ Pre-filtration process: Temporarily cools compressed air from the air compressor to separate dirt and dust. The compressed air is then fed into a condenser to separate the steam. The pre-filter stage is the most necessary stage for compressed air treatment.

+ Drying process: is the processing stage depending on the required quality of compressed air.

+ Fine filtration process: Process compressed air in this stage before putting it into use.

– Water-cooled equipment: To remove water vapor from the gas by reducing the temperature in the water-cooled heat exchanger.

– Air drying equipment: The amount of moisture remaining after passing through the cooler is removed by using an air dryer, because the air used for compressed air equipment must be almost completely dry to avoid causing any damage. abrasion, rust in pipes. Here, moisture is removed using refrigerant.

– Moisture filter traps: Moisture filter traps are used to remove moisture in compressed air. These traps are similar to steam traps. Commonly used traps include manual drain valves, automatic or timed drain valves, etc.

(Source: Ebookbkmt.com)