Automation equipment is a type of production equipment used to automatically perform certain production operations. Specific devices such as industrial robots, automation cells, conveyors, etc.

Automation is the “core” of a developed industry, and the use of industrial automation equipment is the current trend. In Vietnam, more and more factories, enterprises and workshops are applying automation equipment, both to improve work productivity and save a lot of time and costs.

So what is automation equipment ? What types does it include? Let’s find out with Bao Tin through the article below!

What is automation equipment?

Automation equipment is devices that automatically control electrical systems, motors and machines in processing lines in factories, factories, switches in telephone networks, etc.

The biggest special feature of these automation devices is that they replace people to work, helping people save maximum labor, fuel, materials, energy as well as improve efficiency and quality. amount of work with the highest precision.

Nowadays, automation equipment is applied in almost all industries such as water treatment, production lines, packaging, energy monitoring, food processing, high speed cutting machines, printing machines, etc. Embedded programming and design of specialized control systems, in animal husbandry, in the field of traffic, remote control of light signals….

Automation equipment has a wide range of applications. It appears in all modern industrial production and brings convenience to people as well as the appearance of industry.

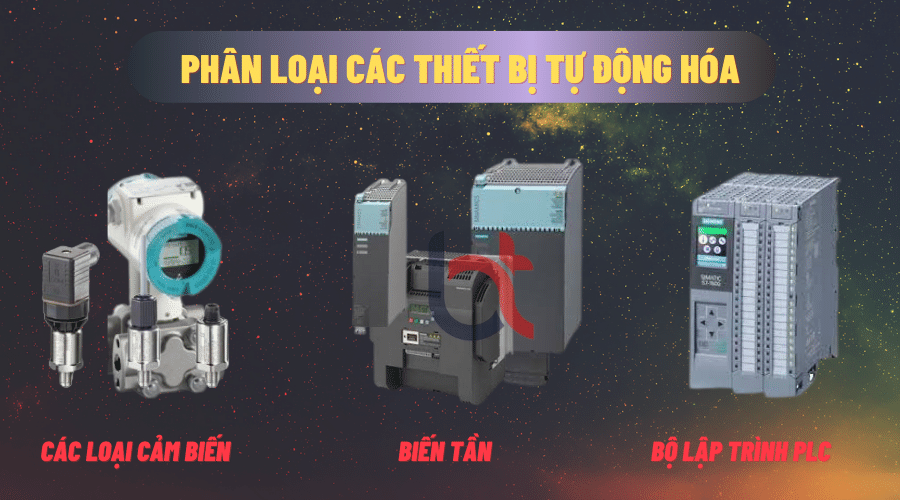

Classification of automation equipment

PLC programmers, HMI screens, sensors, power supplies are automation devices commonly used in industries today.

1. Sensor types

A sensor is an electrical device used to measure signals of pressure, temperature, speed, light, and other external phenomena and factors, and converts them into standard electrical signals. for the controller to process and analyze.

Nowadays, people make sensors from sensoir probes whose electronic part can change properties according to changes in ambient factors. A sensor usually has circuit elements.

People divide sensors into: Passive sensors, active sensors, digital sensors, analog sensors… However, the most common is still the way to divide based on signal elements: Optical sensors, sensors proximity sensor, infrared sensor, pressure sensor…

2. Inverter

The inverter is an “outstanding” device that cannot be ignored in the automation system. It is a device that changes the frequency of the current applied to the coil inside the motor and thereby controls the motor speed steplessly without the use of mechanical gearboxes.

In a production system, there will be many operating devices: electric motors, pumps, motors… They do not work at the same level. With the change in output, the productivity is continuous, the available levels are often not able to meet. The inverter is a smart and useful solution to solve the above conundrum.

What are the benefits of using an inverter: Reducing starting current helps to avoid voltage drops, easily reversing and changing motor speed, avoiding sudden start when the motor is under heavy load, helping the system safe and stable. Because the inverter can be combined with communication modules, monitoring and control becomes easier.

In which the inverter comes from the famous and popular Siemens brand in the market. This is a brand that is always at the top when ranking the largest gas companies in the world, with a variety of types such as V20 inverter, G110 inverter, G120 inverter

3. PLC programmer

The birth of the PLC programmer is considered as a new breakthrough of modern industry. This is a device that changes many previous views about automation control systems. Thanks to the PLC programmer, humans can change the control algorithm easily along with the machine’s fast processing speed and extremely suitable for industrial production environments.

Equipment used for industrial automation. Programmable controllers can automate the operation of one or more other devices that can be an entire production or packaging line. The structure of the PLC programmer includes:

One internal memory (program memory) and expandable by external memory.

A processor circuit has a connection port between the PLC and the input and output modules.

There are different types of PLC programmers based on its main components such as output, input, RAM capacity, counters, memory bits, functions, processing speed, and communication capabilities. It is widely applied in the automation of production lines, garbage and wastewater treatment, high-speed cutting machines.

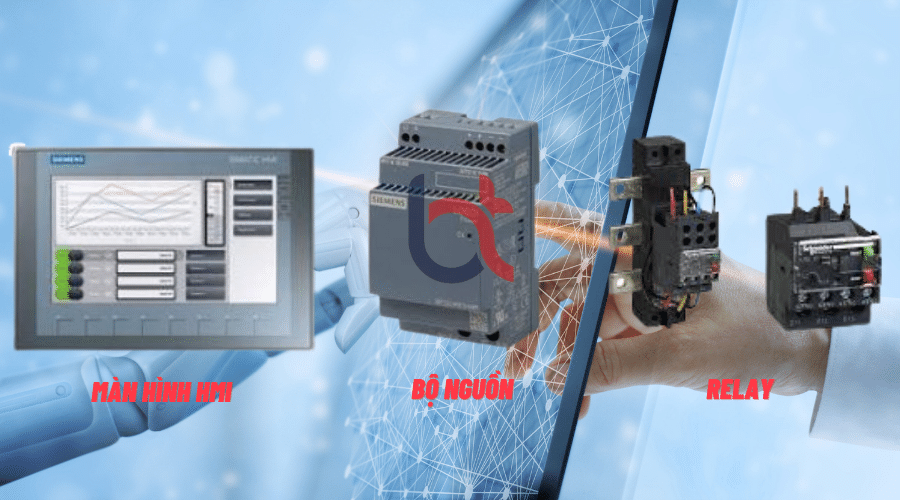

4. HMI screen

HMI screen is considered an interface, which is a very broad term applied to any screen that someone uses to interact with devices. It is an intermediate device between the operator and the automatic machine system, the operator directly manipulates the screen, controls parameters, signals, and operating procedures of the system.

HMI screens are most used in the fields of industrial production, transportation, manufacturing, and animal husbandry. Factory operators use HMI screens to control and monitor ongoing production processes and activities at remote locations without being physically present at that particular location.

The HMI display offers “outstanding advantages” such as:

Good price

In different environmental conditions, the results are compatible with the observation eye

The processing circuit is complicated but the operation is extremely easy

Durable

5. Power supply

Power supplies are power supplies with built-in devices to help people use them quickly and efficiently. It helps distribute power efficiently in the operation of lines and machines to ensure sufficient power and smooth operation.

It is the part that provides power for the operation of other devices. The power supply can be adjusted according to the phase range, specially designed to provide the DC voltage needed for electrical equipment to operate on a safe voltage.

Outstanding advantages of the Power Supply:

Conforms to world standards with quality-assured mode-switching technology

Easy to install, use and replace easily from one application to another

6. Relay

Relay is also known as relay, it is an electromagnetic switch. Operation depends entirely on a relatively small but strange current that can turn on or off a larger current. When buying a relay, it is important to note 3 factors: voltage with maximum amperage as well as optimal trigger voltage.

A relay will have 3 blocks, which are:

Actuator block: The task of generating signals for the control circuit.

Receiving block: The function of receiving a signal from the input and then turning it into a quantity to provide a signal for the intermediate block.

Intermediate block: This block will receive the signal from the receiving block and turn it into a quantity for the relay to act on

summary

Above is a summary of knowledge about what automation equipment is, its advantages and applications in industry. In addition, Bao Tin also briefly introduces to readers the types of electrical automation equipment that are popular and are applied daily in production and industrial control activities. We hope to give readers an overview of the industry and industrial electrical equipment, so that they can effectively apply it to production and automatic control activities for their factories and factories. .